Cleanroom

Quatrefoil designs, manufacures and installs cleanrooms in which the concentration of airborne particles is controlled and which are constructed and operated so as to minimize the introduction, generation and retention of particles inside and in which other relevant parameters such as moisture, temperature and pressure are controlled according to need. In clean rooms installed by us is allowed to run activities sensitive to particle contamination, such as those relating to the manufacture of medical devices to be subjected to terminal sterilization. The properties of air in cleanrooms and associated environments is according to the standard ISO 14644 series of ISO level classified according to the detected concentration of airborne particles of know size. The production enviroment inside the cleanroom are validated suited to processes that take place. We provide extensive documentation on the analysis of cleanroom validantion and final report. All cleanroom provides turnkey. Contac us for further information or request a quote.

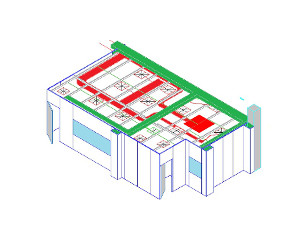

Design

respecting all requests:

- local dimensions

- entrance / exit

- ancillary rooms

Controlled contamination systems

over existing production facilities:

- injection molding / blow molding

- packaging machines

- filling / capping

- industrial automation

- SAS

Tailored enviroments

inserting your production facilities inside:

- washing plants

- production plants

- quality control systems

Mobile structures

that follow your work:

- usable in all enviroments

- guaranteed filtration degree customizable sizes

- softwall / hardwall

- softwall / hardwall

- laminar flow

Indoor facilities

always customizable:

- jib crane

- hoists

- carts

- forklifts

Cooled chillers and heat pumps

designed and sized to guarantee the fixed parameters:

- contamination class

- internal temperature

- relative humidity required

- Pressurizzation

Internal installation

agreed placement of:

- lighting systems

- emergency lights

- electrical outlets

- switchboards

- medical gases

- compressed air

Work at height

if necessary, possibility of: :

- placemente at installations level

- support structures

- complex connections

Reduced spaces

recovery and use of:

- adjacent empty rooms

- subscales

- insoles

- blind areas

Earthquake-resistant structures

if necessary, with documentation of:

- project with calculation report

- final testing

Pavements

remaking and new laying: :

- PVC

- resin bicomponent

- linoleum

Ceilings

rifacimento e posa nuovo :

- drywall

- laminate

Active sanitation

active 24/7 on the entire cleanroom:

- sanitizes surfaces

- removes bacteria, molds, odors

- always active

- eliminates pollutants

Furnishings

stainless steel interiors inside the clean room : :

- tables

- chairs

- shelves

- cabinets

- forklifts

Support

availability to keep your production in our clean room during the extraordinary maintenance works for:

- reconstruction of false ceilings / floors

- cleaning / sterilization of channels

- repairs / scheduled maintenance

- complete installations remakes

- cleanroom move to another establishment

Sector of activity

cleanrooms used in:

- aerospace

- food

- automotive

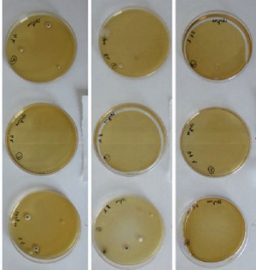

- biotechnology

- chemistry

- printed circuit

- electromechanical

- eletronics

- pharmaceutical

- fibres

- genetics

- research laboratories

- plastic materials

- mechanics

- medical

- microelectronics

- homeopathy

- hospital

- optics

Services

on existing rooms we can carry out:

effettuare:

- validations / recertifications

- refurbishing

- ordinary, scheduled and extraordinary maintenance

- change of class

Components

provision of:

- substitute components

- absolute filters

- pocket filters

- prefilters

- ventilating units